Product Parameters

HOME 1220*2440*18mm film faced plywood – Upscale| Sr NO. | Property | Unit | Test Method | Value Of Test | Result | |

| 1 | Moisture Content | % | EN 322 | 7.5 | Check out | |

| 2 | Density | kg/m3 | EN 323 | 690 | Check out | |

| 3 | Bonding Quality | Bonding Quality | Mpa | EN 314 | Max: 1.68 Min: 0.81 | Check out |

| Damage Rate | % | 85% | Check out | |||

| 4 | Bending Moudulus of Elasticity | Longitudinal | Mpa | EN 310 | 6997 | Check out |

| Lateral | 6090 | Check out | ||||

| 5 | Longitudinal | Mpa | Mpa | 59 | Check out | |

| Lateral | 43.77 | Check out | ||||

| 6 | Cycle Life | About 15-25 Repeated Using Times According To Projects By Formwork Application | ||||

| Sr NO. | Property | Unit | Test Method | Value Of Test | Result | |

| 1 | Moisture Content | % | EN 322 | 8 | Check out | |

| 2 | Density | kg/m3 | EN 323 | 605 | Check out | |

| 3 | Bonding Quality | Bonding Quality | Mpa | EN 314 | Max: 1.59 Min: 0.79 | Check out |

| Damage Rate | % | 82% | Check out | |||

| 4 | Bending Moudulus of Elasticity | Longitudinal | Mpa | EN 310 | 6030 | Check out |

| Lateral | 5450 | Check out | ||||

| 5 | Longitudinal | Mpa | Mpa | 57.33 | Check out | |

| Lateral | 44.79 | Check out | ||||

| 6 | Cycle Life | About 12-20 Repeated Using Times According To Projects By Formwork Application | ||||

| Sr NO. | Property | Unit | Test Method | Value Of Test | Result | |

| 1 | Moisture Content | % | EN 322 | 8.4 | Check out | |

| 2 | Density | kg/m3 | EN 323 | 550 | Check out | |

| 3 | Bonding Quality | Bonding Quality | Mpa | EN 314 | Max: 1.40 Min: 0.70 | Check out |

| Damage Rate | % | 74% | Check out | |||

| 4 | Bending Moudulus of Elasticity | Longitudinal | Mpa | EN 310 | 5215 | Check out |

| Lateral | 4796 | Check out | ||||

| 5 | Longitudinal | Mpa | Mpa | 53.55 | Check out | |

| Lateral | 43.68 | Check out | ||||

| 6 | Cycle Life | About 9-15 Repeated Using Times According To Projects By Formwork Application | ||||

| Film faced plywood Save cost | ||

| Be special for phenolic glue and film | The film faced plywood can be disassembled and used repeatedly for both faces,saving 25% of the cost. | |

| Optimization for the special grade of core | ||

| Be special for adhesive | ||

| Film faced plywood Shorten duration | ||

| Excellent effect of demoulding | Shorten 30% of the duration. | |

| Avoid the reconstruction of the wall | ||

| Be easy to incise and blend | ||

| Film faced plywood the high quality of casting | ||

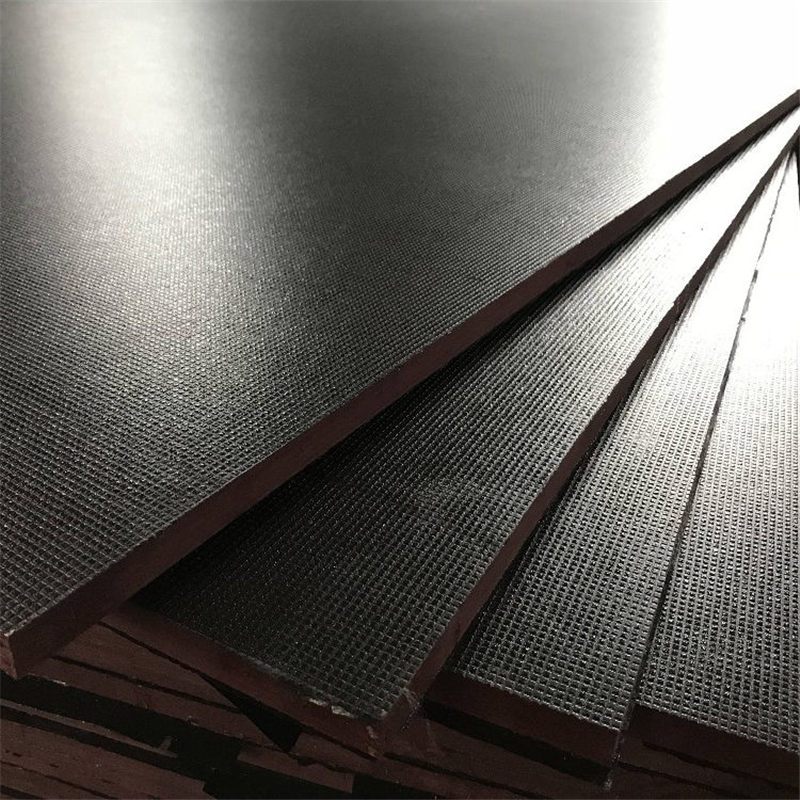

| The flat and smooth faces | The faces are flat and smooth, avoiding bleeding out remains of bubbles and concrete. | |

| The structure of waterproof and breathability | ||

| The edges are polished carefully | ||

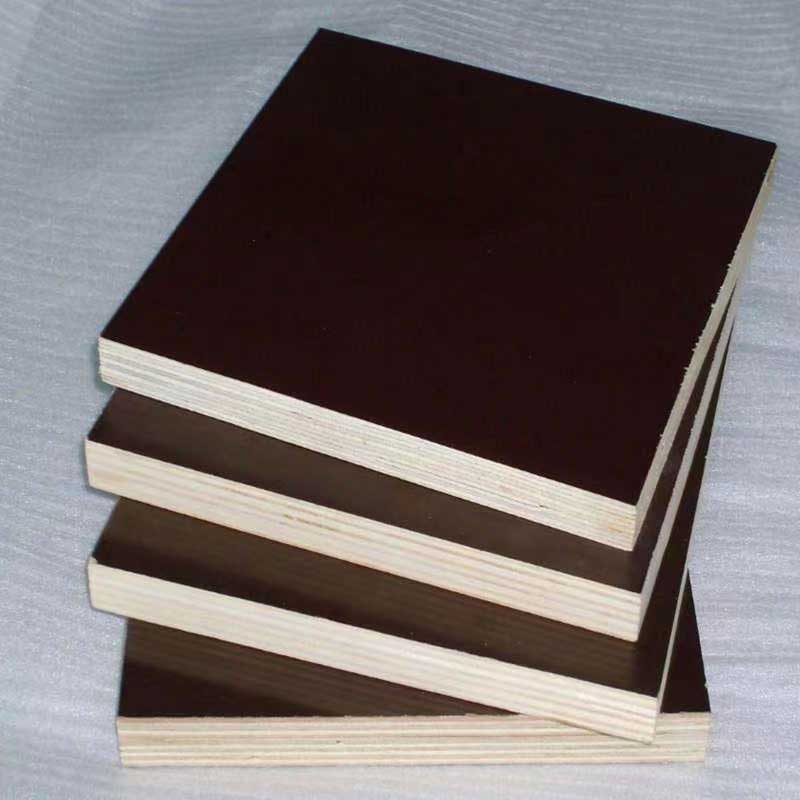

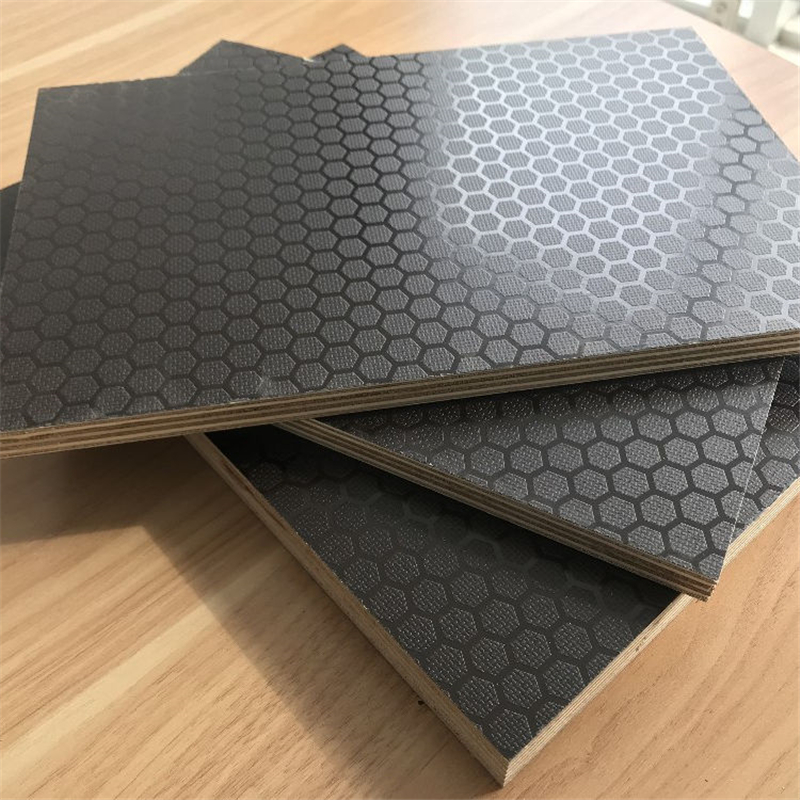

HOME Brown Film Faced Plywood Advantage

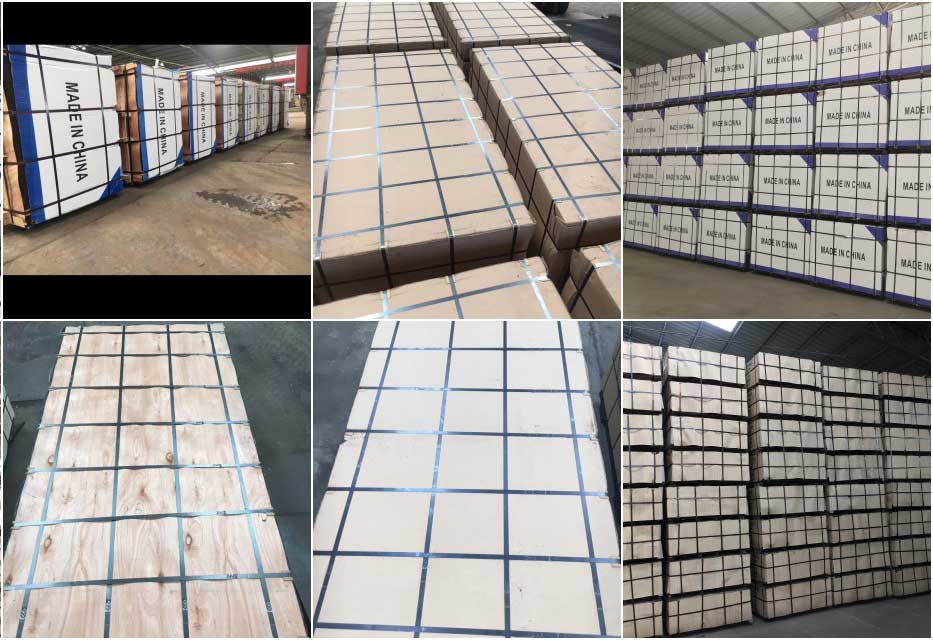

1. Light Weight: We choose the high grade eucalyptus and poplar as the basic material, they are very light, so HOME Brand Film Faced Plywood is convenient for transporting, and only one person could delivery single formwork by hand. 2. Easy To Cut: the plywood is easy to cut, so according to the construction, the formwork could be cut into the required size. 3. Re-used: HOME Brand Film Faced Plywood could be used 8-10 times. 4.Multi Using: HOME Brand Film Faced Plywood could be used for wall, slab, column, beam and bridge concrete pouring etc.. 5. No Deformation: HOME Brand Film Faced Plywood is also whole but not deformation and chipping after 72 hours cooking in boiling water. 6. High Quality Film: HOME Brand Film Faced Plywood is filmed by brown or black film imported from Finland, it protect the formwork surface from the corrosion and makes the formwork durable, improves the flatness of the concrete surface and makes the concrete surface save the second time plastering, so it could save a lot cost of construction. HOME 1220*2440mm Film Faced Plywood Packing And Loading| THICKNESS | PCS/CBM | PCS/20GP(25CBM) | PCS/40HQ(58CBM) |

| 9mm | 37.32 | 930 | 2160 |

| 12mm (7 ply) | 27.99 | 690 | 1620 |

| 15mm (9 ply) | 22.39 | 550 | 1290 |

| F17:17mm (11 ply) | 19.76 | 490 | 1140 |

| 18mm (11 ply) | 18.66 | 460 | 1080 |

| 21mm (13 ply) | 15.99 | 390 | 920 |