Product Description

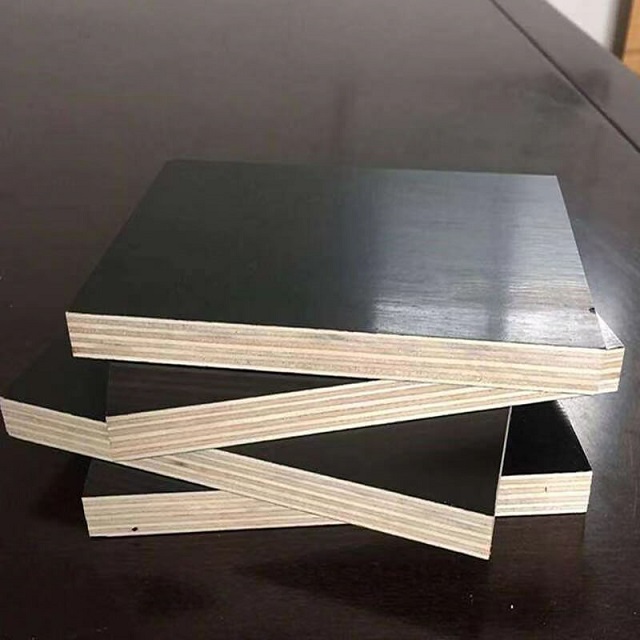

| Name | Film Faced Plywood |

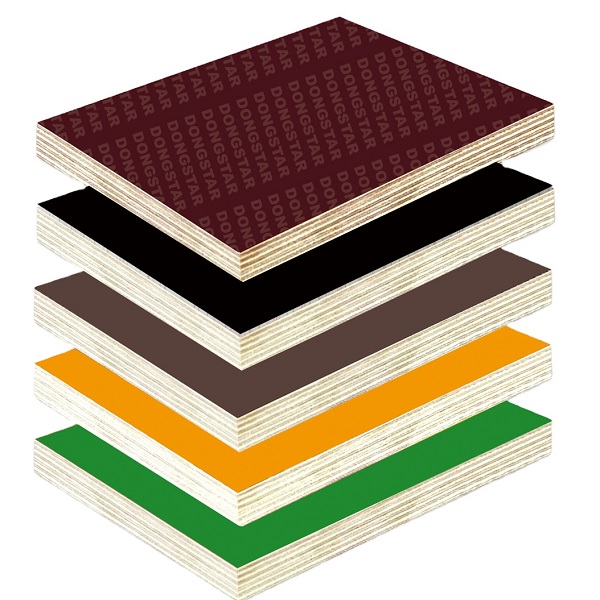

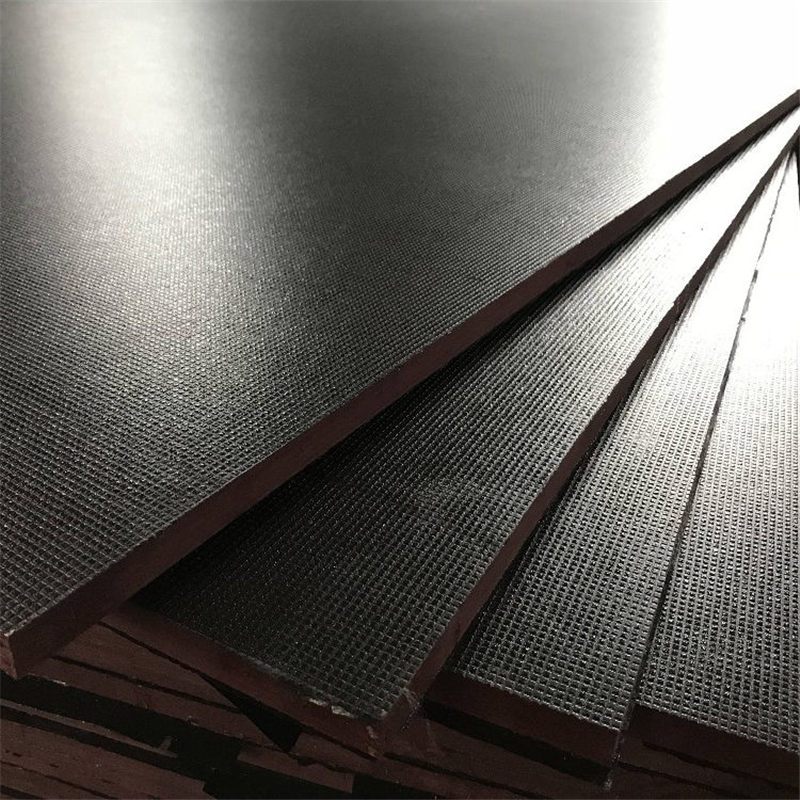

| Face/Back | Black film /Brown film/ Red film Anti-slip etc |

| Core | Poplar /Hardwood /Combi /Finger joint |

| Thickness | 9mm / 12mm / 15mm / 18mm / 21mm |

| Size | 1220*2440mm / 915*1830mm / 1250*2500mm / 1200*1800mm |

| Press Time | One time press/Two time press |

| Glue | Melamine / WBP glue |

| MOQ | 1 x20GP |

| Payment Term | TT/LC |

| Delivery Time | Within 15 days after order confirmed |

| Supply Capacity | 2000 cube per month |

| Certificate | FSC / SGS / ISO 9001 /JAS etc |

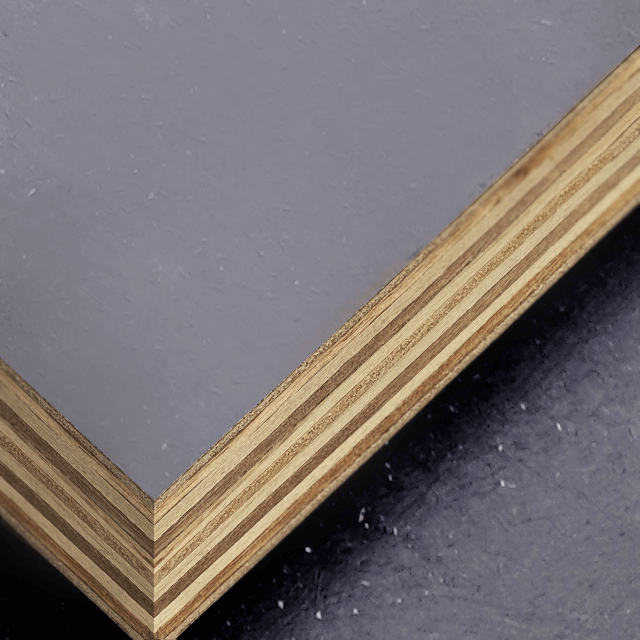

Manufactured From High-grade Full Hardwood Veneers Bonded Together With Custom Made Super E0 Waterproof Adhesive, Which Has Superior Bond Strength.

The oblique joint and hot-melt splicing technology are used to avoid every possible gap.

HOME Formply is a high quality formwork plywood developed and engineered specifically for the Australian market.

With a three tier quality control program comprising;

AA detailed ‘Manufacturing Specification’ adhered to by trained staff;

Regular, detailed and recorded in house testing on key quality requirements and independent grading,

Testing and certification carried out by Certemark Iternational (CMI) and DNV.

HOME Formply provides assurance of quality and consistency.

All veneer in the manufacture is certified Forest Stewardship Council (FSC) from sustainable forests.

HOME Formply is plywood made with a high-density overlay (HDO) of Phenolic resin infused paper bond to give you an amazing off form finish and it’s structural integrity allows multiple reuses across the Concrete, Building and Construction Industries.

HOME Formply for strong, stable, concrete formwork