Product Parameters

HOME 1220*2440*18mm film faced plywood – Upscale| Sr NO. | Property | Unit | Test Method | Value Of Test | Result | |

| 1 | Moisture Content | % | EN 322 | 7.5 | Check out | |

| 2 | Density | kg/m3 | EN 323 | 690 | Check out | |

| 3 | Bonding Quality | Bonding Quality | Mpa | EN 314 | Max: 1.68 Min: 0.81 | Check out |

| Damage Rate | % | 85% | Check out | |||

| 4 | Bending Moudulus of Elasticity | Longitudinal | Mpa | EN 310 | 6997 | Check out |

| Lateral | 6090 | Check out | ||||

| 5 | Longitudinal | Mpa | Mpa | 59 | Check out | |

| Lateral | 43.77 | Check out | ||||

| 6 | Cycle Life | About 15-25 Repeated Using Times According To Projects By Formwork Application | ||||

| Sr NO. | Property | Unit | Test Method | Value Of Test | Result | |

| 1 | Moisture Content | % | EN 322 | 8 | Check out | |

| 2 | Density | kg/m3 | EN 323 | 605 | Check out | |

| 3 | Bonding Quality | Bonding Quality | Mpa | EN 314 | Max: 1.59 Min: 0.79 | Check out |

| Damage Rate | % | 82% | Check out | |||

| 4 | Bending Moudulus of Elasticity | Longitudinal | Mpa | EN 310 | 6030 | Check out |

| Lateral | 5450 | Check out | ||||

| 5 | Longitudinal | Mpa | Mpa | 57.33 | Check out | |

| Lateral | 44.79 | Check out | ||||

| 6 | Cycle Life | About 12-20 Repeated Using Times According To Projects By Formwork Application | ||||

| Sr NO. | Property | Unit | Test Method | Value Of Test | Result | |

| 1 | Moisture Content | % | EN 322 | 8.4 | Check out | |

| 2 | Density | kg/m3 | EN 323 | 550 | Check out | |

| 3 | Bonding Quality | Bonding Quality | Mpa | EN 314 | Max: 1.40 Min: 0.70 | Check out |

| Damage Rate | % | 74% | Check out | |||

| 4 | Bending Moudulus of Elasticity | Longitudinal | Mpa | EN 310 | 5215 | Check out |

| Lateral | 4796 | Check out | ||||

| 5 | Longitudinal | Mpa | Mpa | 53.55 | Check out | |

| Lateral | 43.68 | Check out | ||||

| 6 | Cycle Life | About 9-15 Repeated Using Times According To Projects By Formwork Application | ||||

HOME Film Faced Plywood Advantage

■ If put in boiling water for 48 hours, it is still glue-sticking and non-deformed. ■ Physical mood is better than iron moulds and can satisfy the requirements of constructing mould, the iron ones are easy to be deformed and can hardly recover its smoothness even after repairing. ■ If used abide by the illustrations strictly, it can be reused more than 30 times. ■ Reducing the cost greatly and avoiding the disadvantages from ( rustily and erosive of iron mould) HOME film faced plywood. ■ Solves the problems of leaking and rough surface during constructing process. ■ Particularly suitable for watering concrete project , can make the concrete surface smooth and flat. ■ Realizing a higher economic profits. Meanwhile we also can supply you the formwork systerm accessories, commercial plywood , film faced plywood etc. We specially professional in supplying antislip plywood.HOME 1220*2440mm Film Faced Plywood Packing And Loading

| THICKNESS | PCS/CBM | PCS/20GP(25CBM) | PCS/40HQ(58CBM) |

| 9mm | 37.32 | 930 | 2160 |

| 12mm (7 ply) | 27.99 | 690 | 1620 |

| 15mm (9 ply) | 22.39 | 550 | 1290 |

| F17:17mm (11 ply) | 19.76 | 490 | 1140 |

| 18mm (11 ply) | 18.66 | 460 | 1080 |

| 21mm (13 ply) | 15.99 | 390 | 920 |

Product Description

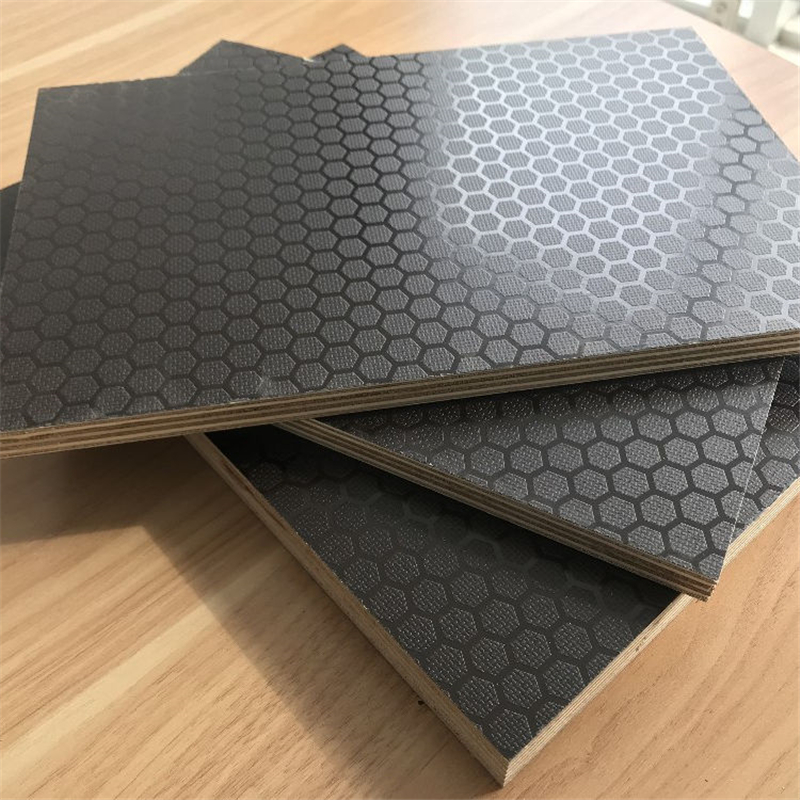

Size: 1220mm x 2440mm (4ft x 8ft); Thickness 9 mm to 21 mm 915mm x 1830mm (3ft x 6ft); Thickness 11 mm to 21 mm Turnover cycle: 10 to 25 times (high turnover times, long service life) Surface material: black, brown phenolic waterproof impregnated paper, pine waterproof paper Glue composition: Phenolic resin adhesive (WBP), triamine adhesive Board core material: poplar core Molding times: two molding, one molding Construction performance: can be processed into various shapes according to the construction needs, nail, saw, drilling performance is better than bamboo plywood, small steel die